Powering the Future: Innovations in Solid State Battery Technology

31 May, 20246 minutes

Â

It isn’t an overstatement to say that without lithium-ion batteries, the world’s portable electronics and electric vehicle industries would not be where they are today. Still, their intrinsic limitations in terms of energy density, charging time, and safety risk have led to intensive research efforts on new-generation technologies poised to replace them.

Solid-state batteries are one of the technologies that have attracted researchers, automakers, and—of course—energy companies in recent years. Thanks to this massive surge in capital invested in solid-state batteries, or SSBs, there have been a number of innovations in this technology in recent years, with the highlights being covered below.

The Promise of Solid-State Batteries

Solid-state batteries, at their core, replace the flammable liquid electrolyte in lithium-ion cells with a non-flammable solid electrolyte (usually some type of ceramic or polymer). The resulting design removes safety concerns over thermal runaway (the major stumbling block for lithium-ion batteries), and can also accommodate lithium metal anodes, which raise energy density substantially.

Solid-state batteries are claimed to provide up to 2-3 times higher energy densities than the current lithium-ion cells, says industry expert Jesús Monforte Hernández, CEO of Optimised Battery Systems. The higher energy density translates into longer driving ranges, higher operational capacities for portable devices as well as grid station upgrades.

In addition, it's anticipated that solid-state batteries will be able to charge many times faster than lithium-ion batteries, taking only 10 to 15 minutes to go from 0 to 80% charge. Combined with the potential for rapid charging, far longer life, and virtually no deterioration of output over time, solid-state batteries are an exciting development in a number of applications.

Overcoming Technological Hurdles

The enormous potential advantages have led many to explore solid-state batteries as the next big leap in energy storage technology, but there are still several serious technical hurdles that would need to be cleared before they could ever become viable for commercial products. A key challenge is the development of solid electrolyte materials that can conduct Li ions well, even while maintaining both chemical and electrochemical stability over many charge cycles.

Researchers at companies like QuantumScape, Solid Power, and Factorial Energy are working with their own variations on solid electrolyte compounds, which include ceramics like lithium lanthanum zirconium oxide (LLZO) and polymer-based materials. Yet still, the solid state of these electrolytes makes it incredibly challenging to control all the mechanical stresses and interfacial issues that occur as a result.

The challenge of scaling up the production processes for solid-state batteries is intimidating, as their production methods are significantly different from traditional procedures. This will require additional human resources, training, equipment, and infrastructure. QuantumScape and its competitors, such as Solid Power (which will deliver solid-state batteries to BMW and Ford by the end of 2026), plan to have commercial production online by 2025 at the latest.Â

Recent Innovations in Solid State Battery Technology

With the SSD industry expanding rapidly, a series of groundbreaking innovations are expected to supercharge the use and acceptance of solid-state batteries.

High-ionic Conductivity Solid Electrolytes

The most significant milestone in solid-state battery technology has been the creation of solid electrolytes that have high ionic conductivity. These materials ensure good ion transport, one of the key requirements for high-performance batteries. Moreover, different electrolyte compositions are being researched for the development of new combination electrolytes that equal or even exceed the ionic conductivity of traditional liquid electrolytes. Examples of such materials include sulphide-based and garnet-type solid-state electrolytes. The use of these materials is set to provide safer and more efficient energy storage for electric vehicles and consumer electronics.

Thin-Film Solid-State Batteries

The integration of thin-film technology has led to ultra-thin solid-state batteries, which are revolutionising the new age of portable electronics and medical devices. These novel batteries are built based on techniques such as atomic layer deposition and have high energy density and flexibility. Their lightweight, compact size makes them a perfect choice for applications where size and weight are critical components, such as drones and satellites. Samsung SDI has emerged as a leader in this technology and is leading the way by introducing compact and high-performance solid-state batteries.

Scalable Manufacturing Techniques

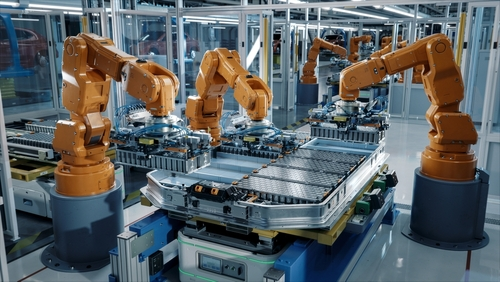

Scalable manufacturing is necessary to bring solid-state batteries to market. Recent developments related to roll-to-roll processing and 3D printing techniques allow for the high-rate production of solid-state batteries on a large scale with constant high throughput. BMW, for example, is currently working with Solid Power to integrate solid-state batteries into their future electric vehicle models, leveraging these scalable manufacturing processes.

Hybrid Solid-State Electrolytes

Another innovation in SSBs is the introduction of hybrid solid-state electrolytes, which combine the strengths of solid and liquid elements. To do this, the electrolytes rely on the high ionic conductivity that can be achieved only with solid ceramic particles in a soft polymer matrix, which overcomes the brittleness and low ionic mobility of pure solid-state electrolytes. This hybrid solution enables a balanced, high-performance electrolyte that helps to further extend the range of possible applications for solid-state batteries.